Af D.G. Horswill og T.H. Nielsen, The Third International Conference on Structures and Architecture (ICSA 2016), Guimarães Portugal, Juli 27 -29, 2016

D.G. Horswill & T.H. Nielsen

Søren Jensen Consulting Engineers, Copenhagen, Denmark

ABSTRACT: PC (precast concrete) construction has a long history in Denmark and has devel- oped into a dominant technology in response to client and contractor demands for a low cost, low risk structural system.

CLT (cross-laminated timber) construction is new to the construction industry in Denmark and has not had the benefits of time and financial investment to be able to compete commercially with PC construction.

In the absence of ambitions beyond low cost and risk, the situation is destined to remain un- changed.

In 2009, Copenhagen announced plans to be the world's first CO2 neutral city by 2025. To- gether with the City's plans to build 6.8 million sqm of new buildings by the same year, a new development trajectory now exists that couples development with sustainability.

While this new incentive may suit the environmental benefits of CLT construction, perceived increased risk and cost represent significant barriers to its adoption in Denmark.

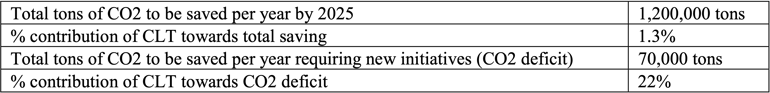

The results of the research show that CLT construction would reduce the existing CO2 deficit of 70,000 tons by 22% - a contribution similar in magnitude to other CO2 reducing initiatives such as the use of solar cells or using new fuels for transport. However, it also shows that the cost of CLT construction is 26% higher than PC construction for the same building.

The paper concludes by suggesting a number of ways to increase the adoption of CLT con- struction in Denmark in light of its environmental advantages and commercial disadvantages.

1. INTRODUCTION

The Copenhagen Resource and Waste Management Plan 2018 states the following:

It is important to have focus on choice of materials and building methods in connection with new building or renovation in order to cause the least possible burden to the environment and mini- mize resource wastage when the buildings are to be demolished or renovated in the future. (WASTEMAN, 2014, p25).

It is clearly a priority of the City of Copenhagen to ensure that the design of new buildings con- siders the environment, both in terms of their initial construction, as well as in terms of their life after their final demolition. But how well does the current Danish construction market support this ambition?

PC (precast concrete) construction consists of pre-fabricated reinforced concrete floor and wall elements which are connected together to form a stable structure. This construction system has a long history in Denmark and has developed in response to client and contractor demands for de- creased risk, increased profits and cost certainty.

In the search for savings, organizations look to improve the cost efficiency of the way they work, often using familiar material and processes – so called incremental improvements (Slaugh- ter, 1998). Such path-dependent development of technologies can lead to the emergence of dom- inant technologies that have had the benefits of scale economies, learning & network effects and the adaption of actor expectations, each reducing cost or risk perceptions (Foxon, 2007). In the context of construction systems, PC construction can be considered a dominant technology in Denmark.

CLT (cross-laminated timber) construction has only been applied in Denmark to a few, very small private projects. Therefore, CLT construction can be considered a novel approach in Den- mark. CLT construction uses prefabricated timber floor and wall elements and is very similar in nature to PC construction in terms of transportation, erection and its underlying structural princi- ples.

By their nature, novel and unconventional approaches have not had the benefit of these path- dependent reductions in risk and cost and as a result are likely to be perceived as more expensive, risky, or both (Jones et al, 2015).

The need for resource efficiency has introduced a new improvement trajectory that threatens profit margins which have been achieved using cost and risk efficient technologies. As such, in the absence of regulation or client direction, a contractor seeking to minimize cost and risk would lack the motivation to adopt such an approach as it threatens the delivery of acceptable rates of return or the winning of projects in a lowest cost auction (Jones et al, 2015).

In 2009, Copenhagen announced plans to be the world's first CO2 neutral city by 2025. To- gether with the City's plans to build 6.8 million sqm of new buildings by the same year, a new development trajectory now exists that couples development with sustainability.

The purpose of this document is to question the dominance of PC construction in light of the City’s new sustainable demands by comparing it with CLT construction and to suggest ways in which to increase the adoption of CLT construction in the Danish construction market.

2. SUSTAINABILITY AND COMMERCE

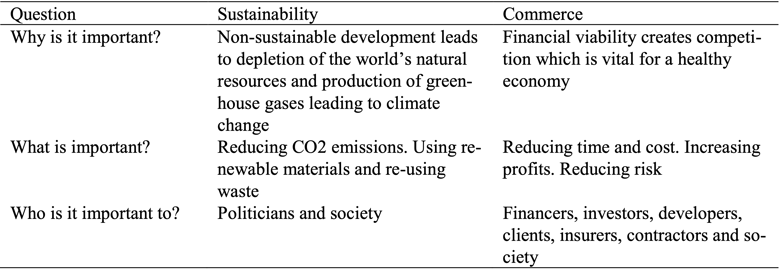

Sustainability and commerce are two important factors that influence the development of con- struction systems. The following table identifies the main issues concerning the importance of commerce and sustainability as well as the key stakeholders to highlight the difference between them.

Table 1 Main sustainability and commerce issues

3. INTRODUCTION TO PRECAST CONCRETE CONSTRUCTION

Concrete is one of the most common construction materials in the world and is used in many different applications. Precast concrete is a sub-group of concrete structures and is particularly popular in Denmark where approximately 90-95% of new buildings employ this system.

3.1. S.W.O.T.Analysis

Strengths

- PC elements are produced in Denmark

- PC elements can be crushed and recycled as fill material under roads and buildings

- PC elements have good acoustic properties

- PC construction is unaffected by rain during construction

Weaknesses

- Concrete production consumes non-renewable natural resources and uses more energy and produces more CO2 than CLT

- PC elements cannot be reused or upcycled

Opportunities

- PC construction is suitable for a wide range of construction applications where timber may not (i.e. below ground structures, tunnels, marine structures, foundations etc)

Threats

- More sustainable solutions, including CLT construction, are being used in other countries as viable alternatives to concrete for certain types of building

4. INTRODUCTION TO CROSS-LAMINATED TIMBER CONSTRUCTION

Timber is a natural construction material and is used in many parts of the world for various build- ing structures. Cross-laminated timber is an example of engineered timber in which small individual timber elements are glued together to form a large-format timber element with specific engineering properties.

4.1. S.W.O.T.Analysis

Strengths

- Timber is a renewable material if produced from managed forests

- CLT production has proven to use less energy and produce less CO2 than concrete

- CLT elements could be re-used, recycled, upcycled, or incinerated to produce energy

- CLT buildings are half the weight of PC buildings which could result in cheaper foundations

Weaknesses

- CLT is not currently produced in Denmark

- CLT elements have poor acoustic properties without additional treatment

- Weather protection of CLT structure needs to be considered during construction

- The current Danish building regulations for fire safety do not permit the construction of more than 4 storeys in timber

Opportunities

- CLT has proven to be a viable alternative to PC for certain types of building including schools and residential buildings

- CLT construction could contribute significantly towards Copenhagen’s ambition to be carbon neutral by the year 2025

Threats

- PC is the dominant construction system in Denmark and cost and risk can be quantified with a large degree of certainty

- Clients and contractors are very risk averse

- PC is very competitive in terms of cost

5. CASE STUDY

In order to compare the performance of PC and CLT construction with respect to sustainability and commercial viability, a case study has been used.

5.1 Background

The selected case study is a competition from 2015 for a housing project in Copenhagen. The architect’s proposal consisted of a number of two and three storey apartment blocks arranged as a series of parallel linear buildings. This project was chosen as it represents a typical residential development in Copenhagen.

5.2 Sustainabilityperformance

To assess the sustainability performance of PC and CLT construction systems, the assessment process has been divided into 3 parts:

- Cradle-to-gate

- Transportation

- End-of-life

5.2.1 Cradle-to-gate

Cradle to gate is defined here as the CO2 produced up to the point where the product is ready

at the factory gate for transportation to site.

For PC, this process consists of the following:

- Extraction of the raw materials from the ground

- Processing of raw materials to produce cement

- Addition of other materials including steel reinforcement, sand, aggregate, admixtures

and water

For CLT, this process consists of the following:

- Harvesting of trees from managed forests including the planting of replacement trees

- Processing of trees into individual timber elements

- Addition of glue, pressure and cutting to size and shape

5.2.2 Transportation

Transportation is defined here as the CO2 produced when the structural elements are transported from the factory gate to the building site. PC is produced in Denmark by a number of manufacturers. However, CLT is not produced in Denmark and has to be transported from Austria.

5.2.3 End-of-life

The Copenhagen Resource and Waste Management Plan 2018 (2014) describes the City’s approach to managing waste including waste from the construction and demolition sector and in- cludes a waste hierarchy as follows:

- Prevention

- Reuse

- Recycling

- Other recovery

- Disposal

Waste arisings must be reduced by promoting direct reuse, allowing products to remain in circulation for a longer time before they place a burden on society by becoming waste that must be managed. In this way resources for the manufacture of new products are saved and less C02 is emitted (WASTEMAN 2014, p15).

PC elements are connected using steel bolt connections which are then infilled with in-situ concrete. The structure is demolished using large, heavy plant creating noise, vibration and dust. The demolished concrete is separated from the steel reinforcement, crushed and recycled as fill material under new roads and buildings.

CLT elements are connected using steel screws and bolts and could be disassembled using hand tools and a crane. The elements could either be reused or recycled into a number of new products including furniture. As a last resort, the timber could be incinerated and converted into energy to help produce hot water as part of the City’s district heating supply.

5.2.4 Carbon calculator

For the purpose of this research, it was decided that CO2 be used as an indication of sustaina-

bility performance. The above process, together with data on the embodied carbon of building materials taken from various sources (EPDCLT, 2012, PCDEC, 2012, PCDEC2 2012), was used to calculate the CO2 impact of PC and CLT for the case study building. A ‘carbon calculator’ spreadsheet was made in order to perform the calculations and compare the various end-of-life scenarios relevant to Copenhagen.

5.2.5 Results

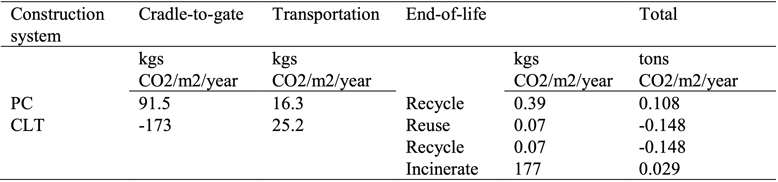

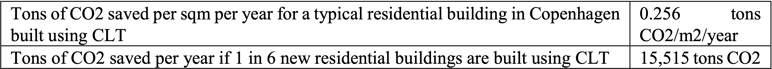

The carbon calculator results are as follows:

Table 4 Carbon calculator results

The amount of CO2 saved when a building is constructed from CLT considers the fact that it replaces a building that would have been built from PC. Therefore, the results of this study show that the total tons of CO2 saved/m2/year is 0.256 (difference between 0.108 and -0.148). The results for both systems includes the CO2 produced by the concrete foundations.

5.3 Commercial performance

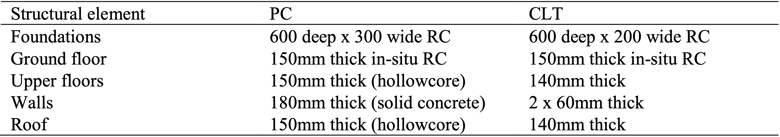

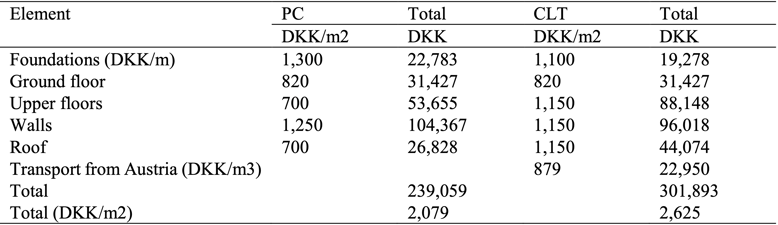

For the purpose of this research, it was decided that cost would be used as an indication of commercial viability. Structural schemes were developed for PC and CLT construction systems for a typical three-storey, three-bedroom apartment with a total floor area of 115m2. Calculations were made to determine the structural size of the different elements and combined with price data (PRISBOG, 2014) to calculate the cost of each system. The study does not consider the cost of the construction period of the structure because PC and CLT construction are assumed to be very similar in terms of construction speed.

5.3.1 Results

The structural calculation results are as follows:

Table 2 Structural calculation results

The cost calculation results are as follows:

Table 3 Cost calculation results

The results of this study show that the cost of CLT construction is 26% higher compared to PC construction.

6. COPENHAGEN 2025

6.1 Background

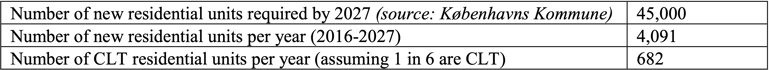

Copenhagen’s politicians have set two targets by the year 2025 – firstly, to be the first city in the world to be carbon neutral and secondly, to build 6.8 million sqm of new buildings to service a predicted population increase of 110,000 new people.

6.2 Copenhagen 2025 Climate Plan

The CPH 2025 Climate Plan (2012) describes the amount of CO2 emissions to be saved per year and how this will be achieved. Copenhagen needs to save 1.2 million tons of CO2 per year. The majority of the saving will be through energy production initiatives but 6% will be through new initiatives in the construction and transport sectors (2025PLAN, 2012, p14). The plan has a reduction deficit of 70,000 tons CO2 for Copenhagen to achieve carbon neutrality (2025PLAN, 2012, p9). It is this deficit that CLT construction hopes to help reduce.

6.3 Building construction systems

The CPH Climate Plan does not refer specifically to any particular building construction system or the effects that different construction systems might have on achieving the CO2 targets in the plan. Therefore, it is assumed that the plan was written according to current construction practice and that this situation will remain unchanged until the year 2025.

Given the results of the previous section, we can draw a number of conclusions which are relevant to the Copenhagen 2025 Climate Plan.

- The use of CLT construction reduces CO2 emissions

- A building made from CLT replaces one that would have been made from PC thereby saving further CO2 emissions

- CLT could be reused, recycled or incinerated to produce energy

6.4 Calculation of CO2 savings

In order to assess the impact of these results on the CPH 2025 Climate Plan targets, the follow-

ing has been calculated:

![]()

In terms of numbers of residential units, the results can be expressed as follows:

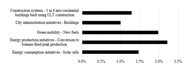

These results can be compared with the CO2 reduction targets from the CPH 2025 Climate Plan as follows:

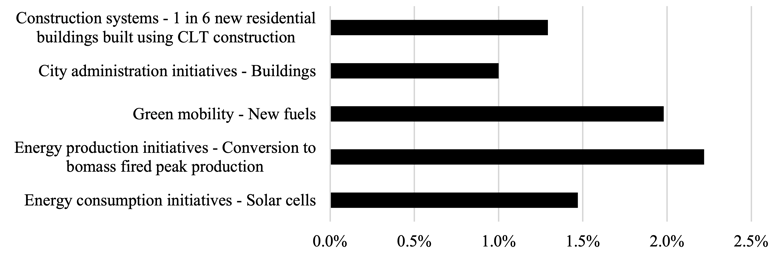

To put this into perspective the results can also be compared with the contribution made by other initiatives which are presented in the CPH 2025 Climate Plan.

Figure 1 Contribution of CLT construction to total CO2 savings target (1.2 mio tons) compared to contri- bution from other initiatives.

7. DISCUSSION AND CONCLUSIONS

The results of this research can be summarised as follows:

- CLT construction eliminates the CO2 produced by PC construction and absorbs more

CO2 than it produces resulting in a nett saving in CO2, which contributes 22% each year to reducing the City’s CO2 deficit of 70,000 tons. Therefore, we conclude that CLT construction performs better than PC construction in relation to the City’s sus- tainability ambitions and contributes significantly to CO2 reduction when compared with other initiatives already included in the CPH 2025 Climate Plan. - CLT construction is approximately 26% more expensive than PC construction for typ- ical residential buildings. PC construction is easily available, well-known and low risk providing cost certainty. Therefore, we conclude that PC construction performs better commercially than CLT construction in the Danish construction market.

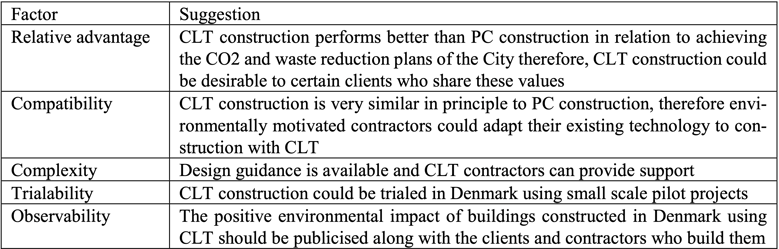

Given that CLT is a novel construction system in Denmark and given the commercial advantages of PC construction, there is clearly a lack of motivation for clients and contractors to adopt CLT. However, given the new improvement trajectory created by the City’s politicians, to reduce CO2 emissions and re-use waste, a motivation for CLT construction has emerged.

According to E. M. Rogers, (Rogers, 2003) there are five main factors that influence adoption of an innovation:

- Relative advantage – the degree to which the innovation is better than what it precedes

- Compatibility – how consistent the innovation is with existing technologies

- Complexity – how difficult the innovation is to understand and/or use

- Trialability – the extent to which the innovation can be tested prior to adoption

- Observability – the extent to which the innovation provides tangible results

This can be used in order to suggest ways in which to increase the adoption of CLT construction in the Danish construction market.

CLT construction also needs the support of politicians starting with its addition to the City’s Cli- mate Plan. However, their support could go further. An example is the ‘Timber First’ initiative developed by the London Borough of Hackney in which the local government has made it part of their planning policy for designers to consider the use of timber construction as well as other forms of construction.

REFERENCES

[EPDCLT] Institute Bauen und Umwelt. 2012. EPD KLH Solid Timber Panels, declaration number EPD- KLH-2012111-E

Foxon, T., 2007. Technological lock-in and the role of innovation. In: Atkinson, G., Dietz, S., and Neu- mayer, E. eds, Handbook of sustainable development. Cheltenham: Edward Elgar Publishing, pp. 140-152.

Jones, K., Dr. Stegemann, J., Carris, J., Dr. Winslow, P., 2015. Exploring underlying barriers to the adop- tion of novel materials in the UK construction industry

[PCDEC] Betonelementforeningen. 2012. Miljøvaredeklaration af betonelementer produceret at betonele- mentforeningens medlemmer

[PCDEC2] Institute Bauen und Umwelt. 2012. Beton der Druckfestigkeitsklasse C 30/37, declaration num- ber EPD-IZB-2013431-D

[PRISBOG] Byggecentrum. 2014. V&S Prisdata, Nybyggeri – Husbygning, Butto. ISSN:1904-5824 Rogers, Dr. E. M., 2003, Diffusion of Innovations, 5th Edition – Free Press, ISBN 10: 0743222091

Slaughter, E. 1998. Models of construction innovation, Journal of Construction Engineering and Manage- ment, 124(3) pp. 226-231.

[WASTEMAN] Københavns Kommune. 2014. Ressource and Waste Management Plan 2018

[2025PLAN] Københavns Kommune. 2012. CPH 2025 Climate Plan