Af Peter Vejrum og Kristian Flyvholm, IASS konferencen i Boston, August 16 - 20, 2018

Peterr VEJRUM*, Kristian FLYVHOLMa

Søren Jensen Consulting Engineers Åboulevarden 70, 8000 Aarhus C, Denmark

pve@sj.dk

1. ABSTRACT

The following paper describes the unique result of a partnership between artist and engineer to create an abstract sculptural art piece, in the form of a 3 mm thin, gold covered, 3D-printed shell structure. The shell was form-found based on information extracted from the artist’s paintings.

With only few months to complete design and fabrication we began this unusual interdisciplinary experiment by conceptualizing a structure that needed to act as a pavilion for a relay race but also as a sculpture in the artist’s exhibition. During design, the artist got increasingly fascinated with computer glitches and we set out to create an algorithm that would interpret information in the artist’s paintings and use that information to form-find a shell structure with a glitch-like aesthetic. The developed generative algorithm would extract color data from the artist’s paintings and map the data to a predetermined initial free form surface. The artist would then select a painting, in a range of paintings, for which the algorithm should return the desired initial shape. The algorithm was calibrated to return the initial shape for only this painting. Whenever any other painting was loaded into the algorithm the shape would be deformed based on color distance information in the painting resulting in deformed and glitchy shapes. Deformation was handled by discretizing the initial shape into a mesh and creating a node-spring-system where forces were applied to nodes based on color distance data in the paintings. The generated shell form was then printed on one of the largest SLA-printers in the world and hand gilded.

KEYWORDS: Art, sculpture, color data, paintings, generative modelling, morphology, 3d-printing, glitch, stereolithography, digital manufacturing, particle spring system

2. INTRODUCTION

Søren Jensen is consultant-engineering company where innovation and new design ideas is one of the keystones of the company profile. We pride ourselves in enthusiastically experimenting with new technologies and design methodologies. It is what we do for fun. We set aside time for what we call knowledge sprints where we, through short bursts of creativity, test and develop new methods and tools. One of such yearly experiments is the erection of a temporary pavilion structure for an annual relay race that takes place during the summer in our home town of Aarhus. We use this opportunity to design a unique showcase structure through generative algorithms while combining unorthodox building materials and fabrication methods. We have previously presented one of these pavilions, Polyshell (Bak, Horswill, Vejrum & Nielsen, 2015 [5]), at IASS 2015.

In the spring of 2017 we invited renowned Danish artist Erik A. Frandsen (hereinafter referred to as Frandsen, or simply, the artist) to participate in designing our next pavilion. We wanted to challenge what we thought a pavilion could be, and for that we needed someone who would think unlike us engineers. Frandsen was finalizing an exhibition of works he had made during his travels to Haiti. He planned to make a large sculpture for the exhibition and we agreed that we would design our next pavilion to act both as shelter for the relay race and as a sculpture for his exhibition. The art piece was dubbed “Shelter” by the artist which it hereinafter will be referred to.

Frandsen initiated his career in the 1980s and was at the time known as one of the wild and upcoming artists in the Danish art scene. His artworks consist of several layers where the background layer contains the motive such as a still life or a photograph of a fleeting moment. He then obstructs the motive by adding additional disruptive layers (See figure 1). Frandsen has named these layers “blockades”. A central aspect of his art pieces is to capture fleeting moments and transforming them into a permanent state, where they will live forever obstructed by his “blockades”.

Figure 1 Art installation by Erik A. Frandsen: Alexanderschlacht IX, engraved steel, 200 x 400 cm, 2011.

[Photo credit: Jan Søndergaard]

While pitching design ideas for Shelter, Frandsen was very interested in exploring how computer “glitches” could be implemented as a new type of “blockade” for this artwork. A computer glitch is a temporary fault state within software or electronics that manifests into a visually expressive error. Frandsen wanted to capture one of these faulty states in a permanent allegorical three-dimensional form. In one of our early design meetings Frandsen raised a question that would steer our following design approach: “What happens when a 3D-printer runs amok, glitches, misinterprets instructions and prints something unexpected?”. To try and answer this question, we tasked ourselves in developing an algorithm that would deliberately fail in trying to translate a painting into a three-dimensional form. We approached this by building an algorithm, that when presented with a specific painting, would return a predetermined three-dimensional form and then explore the outputs when we loaded different paintings into the algorithm. The paintings were created by the artist in his travels to Haiti where he would sit in the water edge and try to quickly capture the moment and scenery (See figure 2).

We knew that the resulting geometry would be complex due to the expressive nature of glitches, and decided to have Shelter be 3d-printed, thus removing most of the fabrication limitations. It also allowed us to attempt to answer the question raised initially by Frandsen.

Figure 2 Paintings created by E. A. Frandsen in his travels to Haiti.

3. DESIGN METHODOLOGY

The entire generative algorithm used to create Shelter was written within the parametric modelling environment Grasshopper® (McNeel & Associates, 2018 [2]).

3.1 Initial shape

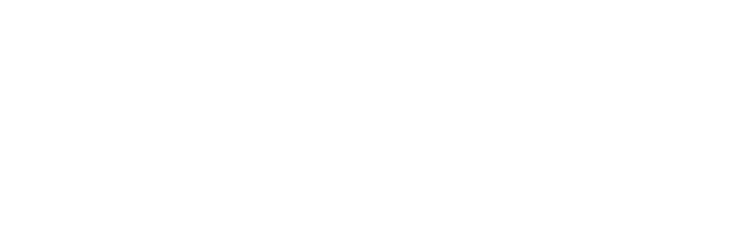

We needed a basic geometry to function as the initial shape that the algorithm should output when fed a predetermined ‘key’ painting. We experimented with different initial basic geometric shapes such as spheres and polyhedrons. Each of these basic geometries needed a different methodology to unroll and discretize the shape which allowed us to map color data to the surface as explained in 3.2. The artist settled on an initial shape modelled as the simplified hull of a ship flipped upside down and cut in half. This made unrolling simple. The hull shape fit the theme of the paintings from Haiti, and the double curved nature of the hull shape would provide the shell with structural rigidity through membrane action, making it a good input for a shell that should cover as much area as possible while keeping material thickness to a minimum. The initial shape was parametrically modelled to allow us to explore different results (See figure 3).

Figure 3 Parametric modelling of the half hull of a ship.

The initial shape was discretized into a quadrilateral mesh by subdividing the Surface into a u,v-grid. The coarseness of the grid could be controlled by changing the subdivision parameters resulting in different aesthetics of the final form.

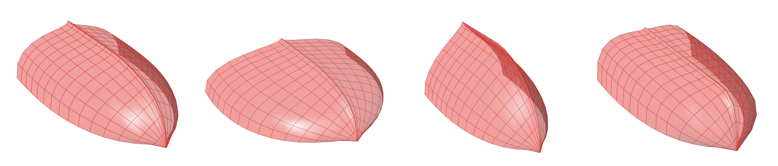

3.2 Extracting color data from the paintings

The artist’s paintings were digitally scanned into image files that could be loaded into the algorithm as bitmap files. A bitmap file is essentially a grid of pixels where each pixel, or point, contains a vector of the amount of red, green and blue contained in the pixel. We referenced the open source .net library ColorMine (Zack, J, 2018[4]) into the algorithm. We could then extract color data in the paintings using the functionalities within the ColorMine library. The mesh of the initial shape was unrolled onto the image file and the RGB-values were read in each grid vertex (See figure 4).

Figure 4 Extraction of color data from the painting in the vertices of the unrolled initial shape.

To achieve a singular numerical color data value in each vertex, we decided to calculate the simple linear color distance, of each vertex color, to a color chosen by the artist. Color distance describes how far two colors are from each other within a three-dimensional color space and thus represents how different the two colors are.

Distance = √(Red2 - Red1)2 + (Green2 - Green1)2 + (Blue2 - Blue1)2

The color distance values were then mapped to the vertices of the mesh representing the initial shape and used to distort the initial surface.

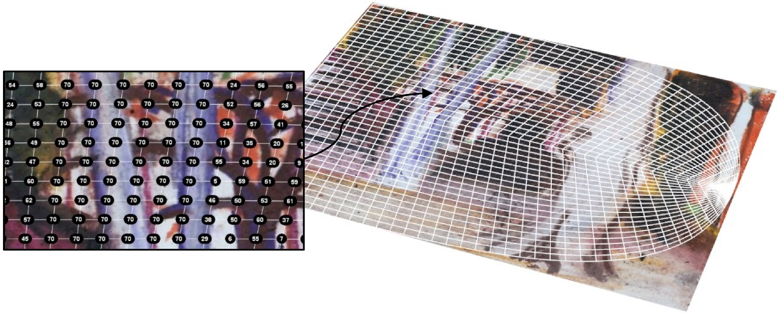

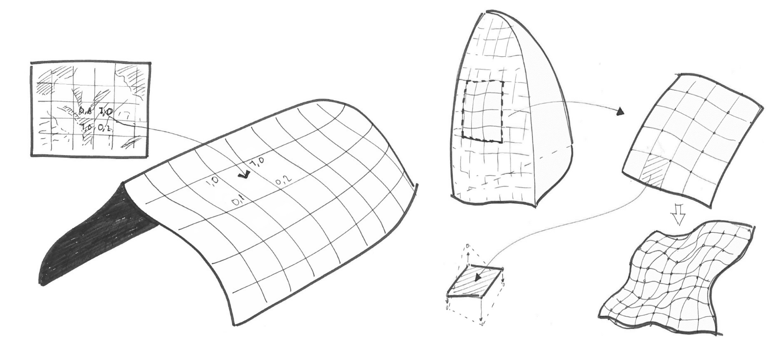

3.3 Deforming the mesh

Using a physics engine within Grasshopper (Piker, Kangaroo, 2018 [3]) the mesh was transformed into a particle-spring-system and relaxed using dynamic relaxation (Barnes, 1999[1]). In traditional dynamic relaxation uniform load vectors are applied to nodes in a particle system to find an optimal form of membrane or shell structures. In our case we wanted to implement dynamic relaxation to distort the initial shape while keeping the shape coherent. As we did not want to fix nodes, and limit the expressiveness of the artwork, we needed to abort the relaxation process after a few timesteps as the relaxation would never converge towards an equilibrium with our chosen constraints. We let the load vectors be the surface normals in the vertices of the discretized initial shape in an attempt to virtually blow up the initial shape. The load vectors were multiplied by the mapped color distance to which we added a numerical amplifier that enlarged large color distances for a more expressive output (See figure 5).

Figure 5 Mapping of data and principle of deformation.

We needed to ensure that the algorithm would output the undeformed initial shape when the selected key painting was loaded. To achieve this, we offset all load vectors with the color data found within the key painting.

3.4 Glitch morphology

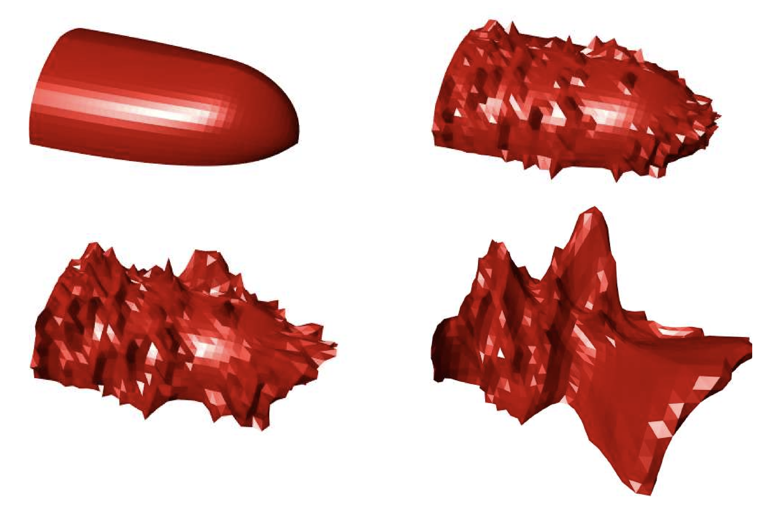

We triangulated the quadrilateral mesh for a crystalized glitchy appearance. When loading a painting into the algorithm (other than the key painting) the initial shape was immediately transformed into a new glitchy three-dimensional representation of the painting (See figure 7).

The paintings made by the artist contained large shapes of uniform colors such as bodies of water, palms and huts. These large shapes were expressed in the deformed mesh were the color distance to the chosen color was great, due to the many amplified neighboring load vectors. Other smaller deformations expressed themselves as noise in the deformed mesh.

Figure 7 The deformation of the initial shape occurs in incremental timesteps.

3.4 Fabrication

The complexity of the form found shape made it ideal to use 3d-printing as a mean to manufacture the shell, while staying true to the initial question raised by the artist. When we initially approached the manufacturers, we were asked to re-send the file containing the 3d-print job, because they thought the file was corrupted, due to the glitchy appearance of the mesh. We had to repeatedly reassure them that the presented file was indeed what we wanted to end up with in physical form.

We quickly realized, that making Shelter in a size that allowed it to function as a proper pavilion was out of our reach with our given budget and the current prices of large scale 3d-printing. We settled for a 2.3 x 1.9 x 1.5 m design and had the shell printed by the manufacturing firm Materialise in Belgium using their Mammoth stereolithography printer, which is one of the largest in the world (See figure 8). The Mammoth printer uses UV-laser to harden a liquid resin building the structure from bottom to top. It was printed in a transparent plastic ABS-like material with low wall thickness (3mm) to reduce overall shell volume and keep cost to a minimum. The 3d-printed material was somewhat brittle so lowering weight, and with it, out of plane bending was essential. We also decided on a shape for Shelter with a lot of three-dimensionality to further improve structural rigidity. The shell was printed in 8 different parts and glued together with inward facing 10 mm flanges. Once completed the structure was hand gilded.

Figure 8 Pieces for shelter right after completion of print job.

4. DISCUSSION AND CONCLUSION

With Shelter we succeeded in creating something truly unique. We set out to design a pavilion for our annual relay race but ended up creating a novel computational method for creating abstract pieces of art from data within paintings. This was certainly only achieved through the interdisciplinary partnership between artist and engineer who both usually operate in very different ways. We found it healthy to cast aside our premonition of what things, such as a pavilion, are supposed to be and will try to transfer some of that mindset to a business where the statement, “This is how we’ve always done it”, is spoken too often.

With Shelter we failed to create a shell that would properly function as a pavilion due to the costs of our chosen manufacturing method. Shelter, when faced upwards, could only actually shelter one person. We feel confident that the quality and strength of the chosen print method is good enough to create larger structures in the future if the cost should go down as the technology is improved. As of now, creating large scale prints with a high level of finish, is still hugely expensive. Prices are governed by the amount of material needed which scales exponentially when scaling geometry.

Figure 9 Shelter exhibited in the artist’s exhibition.

Figure 10 3d-model(left). Shelter at the relay functioning as a gathering point for Søren Jensen (right).

5. ACKNOWLEDGEMENTS

We would like to thank Erik. A. Frandsen for the opportunity to collaborate on creating Shelter.

REFERENCES

[1] M. R. Barnes, Form finding and analysis of tension structures by dynamic relaxation, International journal of space structures, 14(2), 89-104, 1999

[2] R. McNeel, & Associates, Grasshopper - Generative Modeling for Rhino, Accessed April 2018 from http://www.grasshopper3d.com, 2018

[3] D. Piker, Kangaroo. Accessed April 2018 http://kangaroo3d.com/, 2018

[4] J, Zack, ColorMine, Accessed April 2018 https://github.com/THEjoezack/ColorMine, 2018

[5] A. Bak, D. Horswill, P. Vejrum, T. Nielsen, Computational design of a temporary lightweight shell with minimal thickness, Proceedings of the International Association for Shell and Spatial Structures (IASS) Symposium, 2015